THE MATTER WAR

ANTI-MATERIAL AGENTS VERSUS PRO-MATERIAL AGENTS

an anti-material agent were then hijacked and weaponized by an enemy state or organization?

biological agents became maintenance and repair tools like any other?

living organisms turned out to be simply the best protection against anti-material agents?

Iron-eating bacteria, wood-decaying fungi, calcifying microalgae... Living organisms are teeming with agents capable of interacting with materials in a targeted manner.

When misused or even weaponized, some of these biological agents can alter, neutralize, or destroy strategic infrastructure and equipment. The action of these anti-material agents, often invisible and with delayed effects, represents a major risk in a context where France and Europe are facing increasing vulnerability in their supply of strategic raw materials, such as metals and rare earths.

When used wisely, other microorganisms can be valuable allies in protecting, strengthening, and even repairing the materials we use. These pro-material agents are particularly useful in dangerous areas that are difficult for humans to access, where conventional repairs would be perilous.

These discoveries open up a new paradigm that invites us to rethink our relationship with matter, to understand its fragilities and exploit the possibilities offered by controlling its degradation and recomposition.

learn more about the different agents

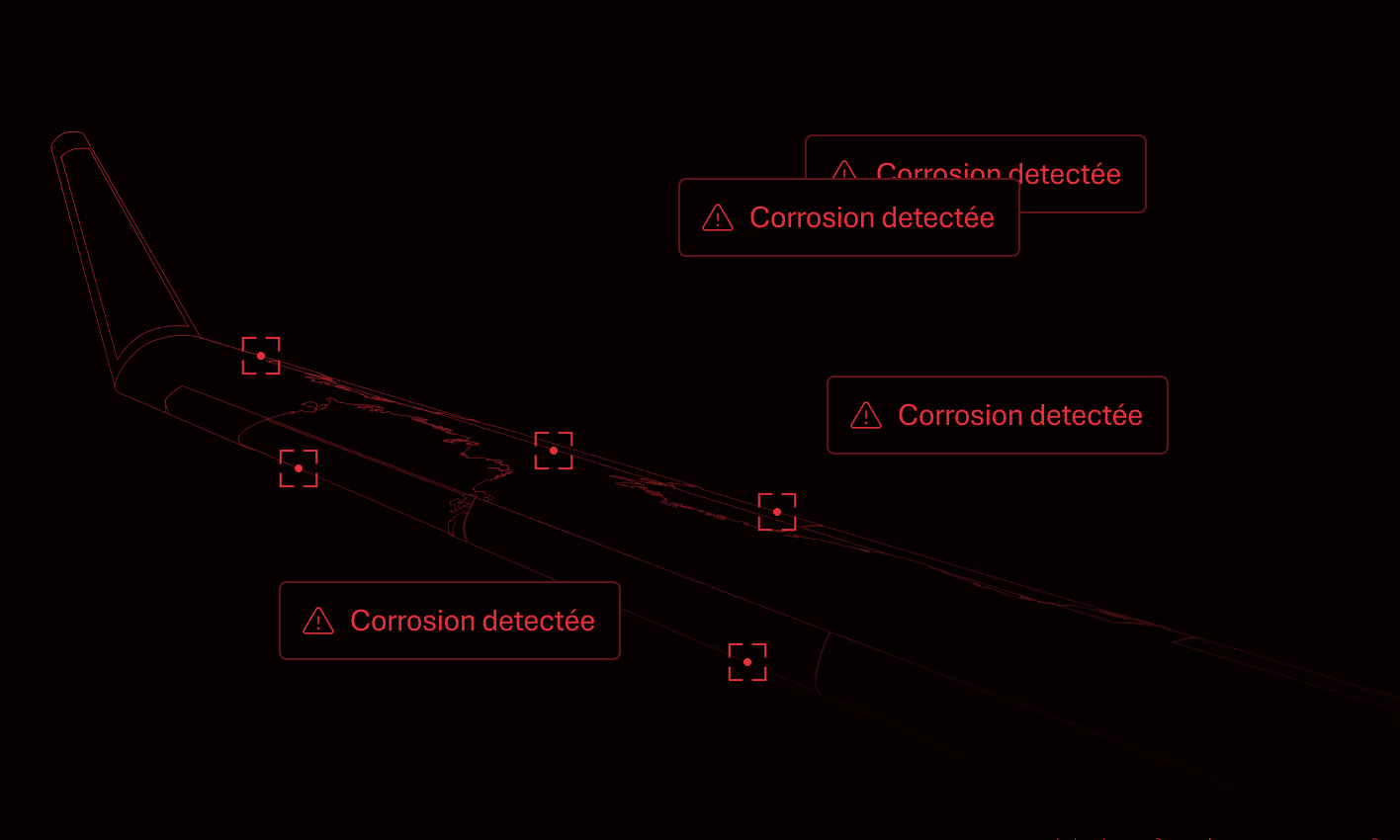

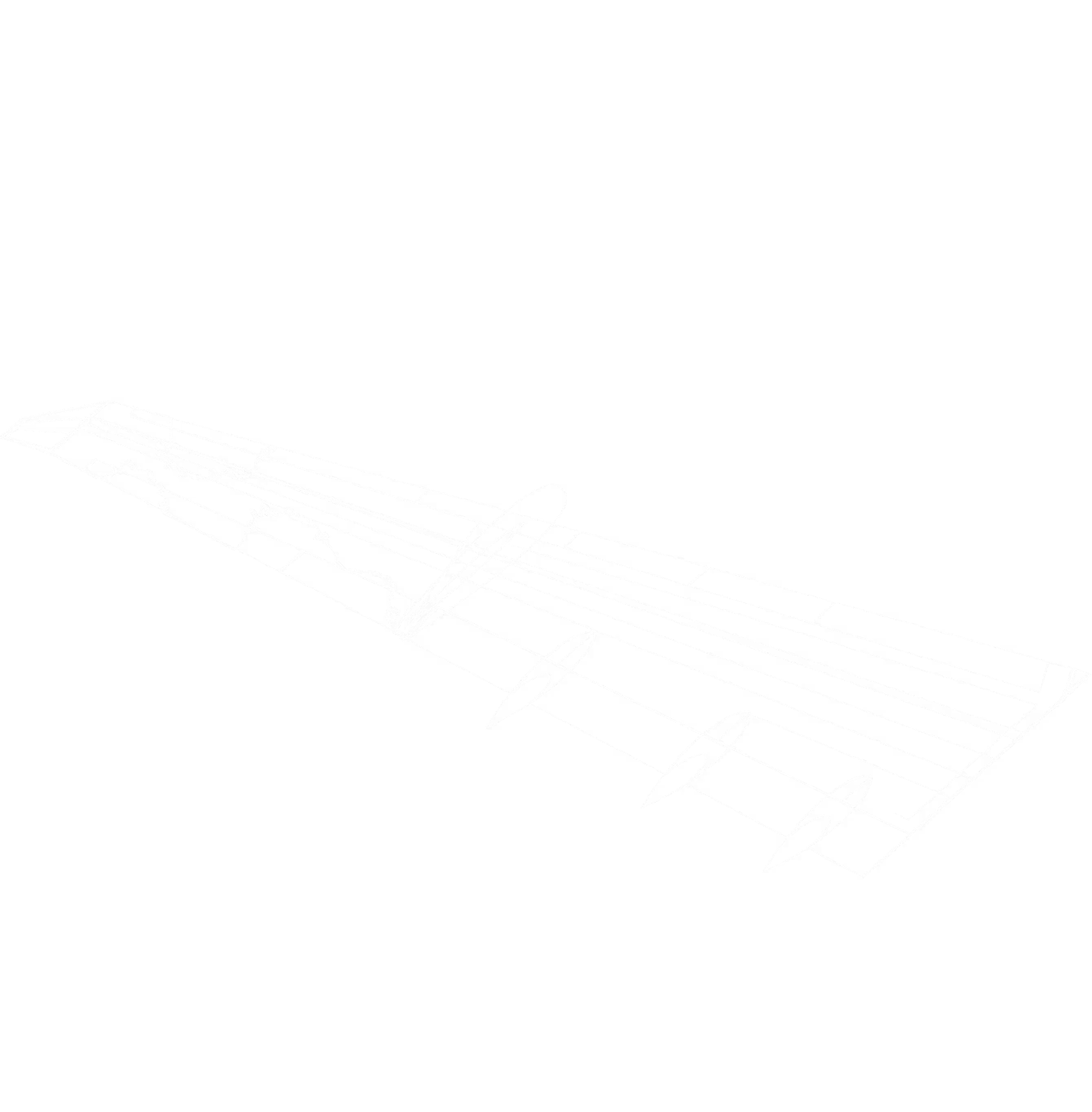

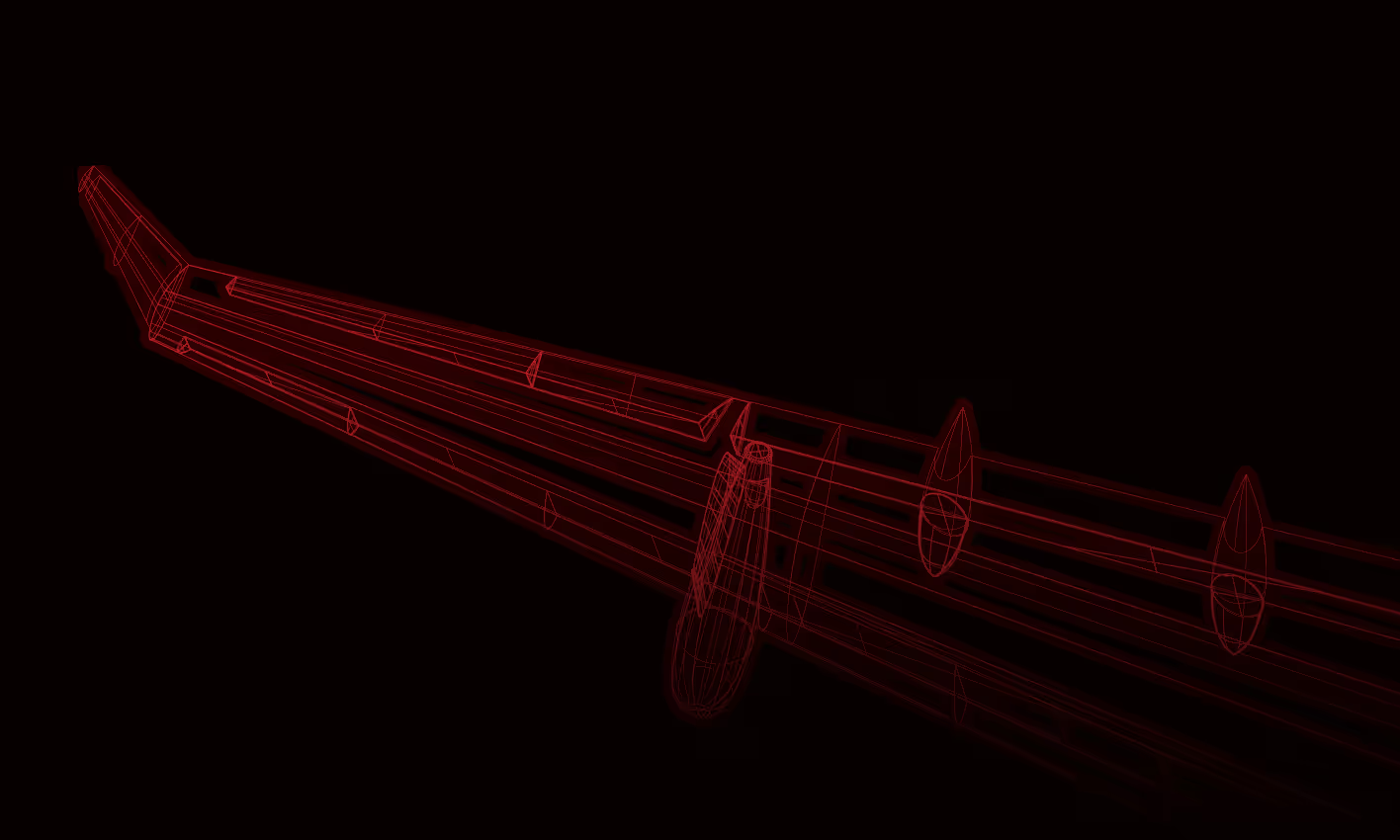

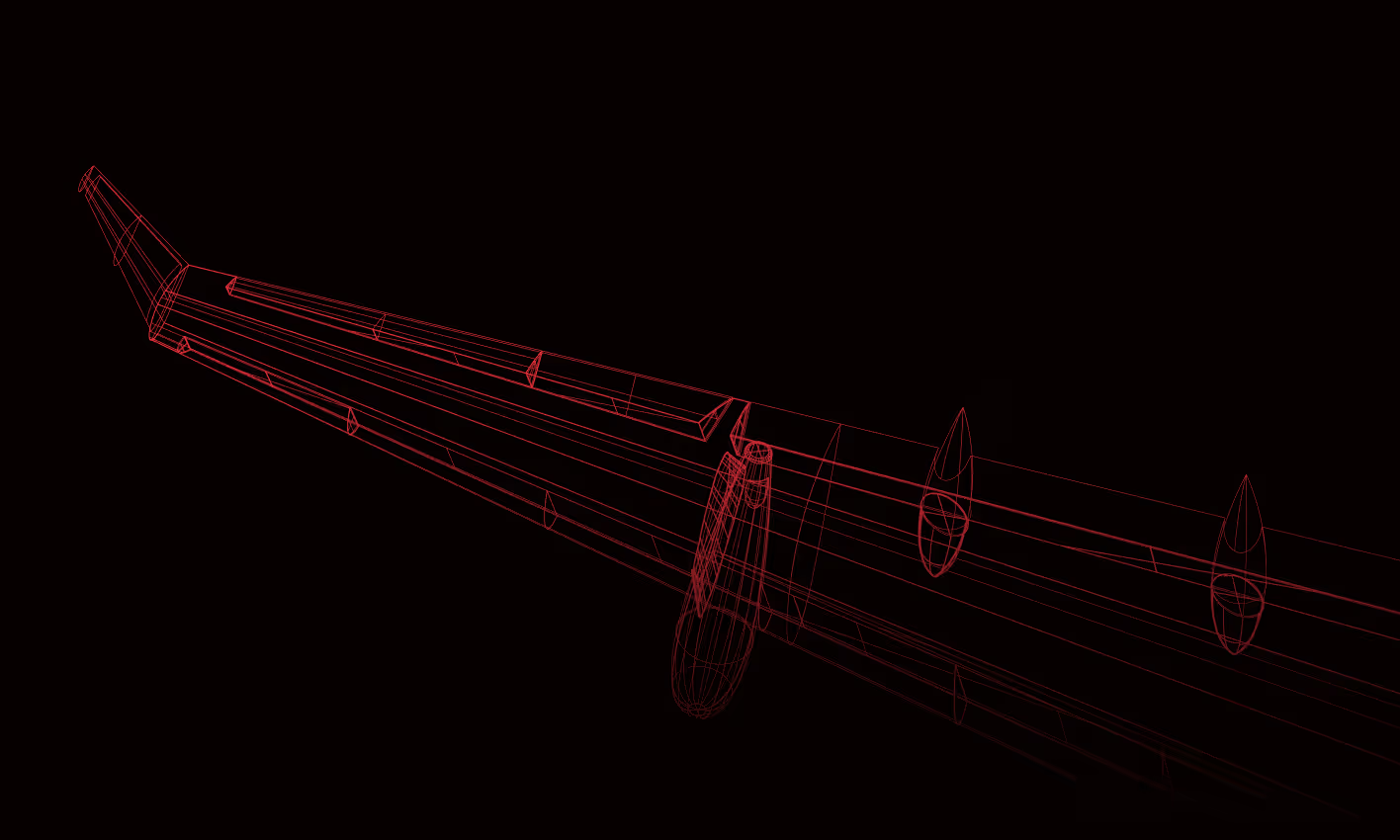

The Airbus A330 Multi Role Tanker Transport (MRTT), whose wing is shown here, is a military transport and refueling aircraft developed and built by Airbus Defense and Space. It can carry up to 60,000 kg of jet fuel to refuel other aircraft.

March 2035

Torrential rain is falling on Air Base 125. Spores of Hormoconis resinae, present in the air, seep into the kerosene tanks of refueling aircraft. Thriving in the humid atmosphere, they multiply. Spraying biocide reassures maintenance technicians: at first glance, the contamination appears to have been contained.

May 2035

A pump fails during refueling over the Atlantic. The fleet makes an emergency landing at Cayenne military airport. While the exterior of the aircraft appears normal, a closer inspection of the fuel tank reveals extensive corrosion marks: the aluminum on its surface is corroded, some pipes unusable.

L’examen est sans appel : Hormoconis resinae is also beginning to colonize the wing structure. The same observation can be made under the epoxy coating of the wing.

The A330 will remain grounded.

Selection of two ANTI-MATERIAL AGENTS

Hormoconis resinae

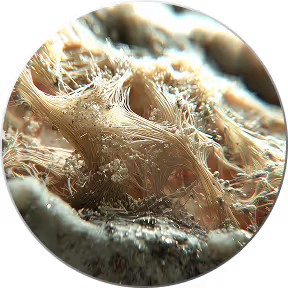

This fungus thrives in environments containing alkanes and water. This is the case in aviation fuel tanks, hence its nickname “kerosene fungus.” The consumption of hydrocarbons by Hormoconis resinae in an aqueous environment—due to condensation formed at altitude—generates organic acids, which corrode aluminum and its alloys.

Fuel tanks and pumps, refueling hoses, and the wing coating of the A330 MRTT are affected.

Pseudomonas aeruginosa

This bacterium is capable of colonizing polymer surfaces and forming a biofilm that traps moisture and nutrients.

By secreting enzymes, it then attacks the chemical bonds of the materials, causing depolymerization.

Microcracks appear on the surface of coatings (paint, epoxy), joints lose their watertightness, accelerating the deterioration of the wing.

The Airbus A330 Multi Role Tanker Transport (MRTT), whose wing is shown here, is a military transport and refueling aircraft developed and built by Airbus Defense and Space. It can carry up to 60,000 kg of jet fuel to refuel other aircraft.

June 2038

A maintenance technician sprays a product onto an A330. At first glance, this seems like a routine scene at the Bordeaux-Mérignac air base. However, a group of scientists is watching closely. This is actually the first real-world test of a revolutionary anti-corrosion product called NatureGuard™, developed by the start-up Greenova, which has been funded by the Defense Innovation Agency since 2036.

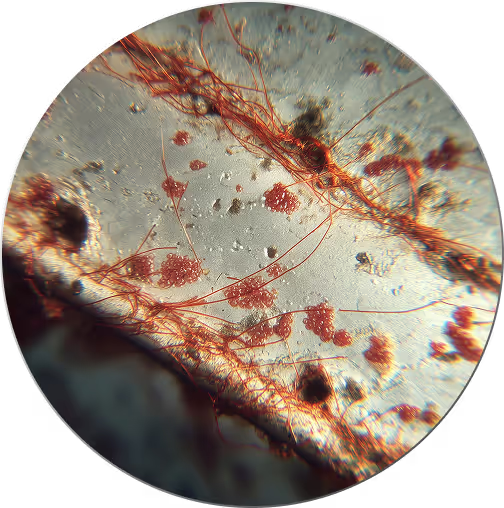

It contains Pseudomonas putida, a bacterium that is particularly resistant to UV rays and capable of growing in a wide range of temperatures and pressures.

The observation will last four days, during which time the aircraft will be used in a refueling mission over the Mediterranean. If all goes according to plan, the bacteria present in NatureGuard™ should have formed a protective biofilm over the entire surface of the aircraft.

In the laboratory, the corrosion rate was reduced by 28%. The Greenova teams hope to see similar results after a flight so that they can roll out the use of this technology across all Air and Space Force aircraft.

Selection of two pro-MATERIAL AGENTS

Pseudomonas putida

This bacterium is capable of forming a biofilm that inhibits corrosion of mild steel. It is possible to improve the biopassivation of the surface by stimulating bacterial activity through the addition of nutrients.Cette bactérie est capable de former un biofilm inhibant la corrosion de l’acier doux. Il est possible d’améliorer la biopassivation de la surface en stimulant l’activité bactérienne par un apport de nutriments.

The biofilm developed adheres to the surface of mild steel even after the bacterial cells have died, providing additional, long-lasting protection for the wing of the A330 MRTT.

Bacillus al-kalinitrilicus

Researchers at Delft University are working on self-healing concrete processes. This research is based on incorporating Bacillus al-kalinitrilicus bacteria and calcium lactate into clay capsules, which are added as aggregates during concrete production.

The capsules crack at the same time as the concrete and cause bacterial activity, which leads to the production of calcium carbonate that fills the cracks.

menaces 2035

Menaces 2035, an unpublished report published by the RADAR Collective by Robert Laffont, imagines and explores the threats of tomorrow based on collaboration between civil society and the defense sector.